New pressing plants are popping up all over the world. That's a good thing, isn't it?

Switzerland has its own pressing plant again and new factories have also opened in Germany, the UK and Taiwan. Is this the long-awaited relief for the tense vinyl market?

Update (October 13, 2022): With Doca Vinyl in Champagne, another pressing plant starts operations.

Complaints about long waiting times for vinyl production are now old news. Since the major labels have started pressing their big stars on vinyl again, small indie labels are having a hard time and the call for more production capacity is getting louder.

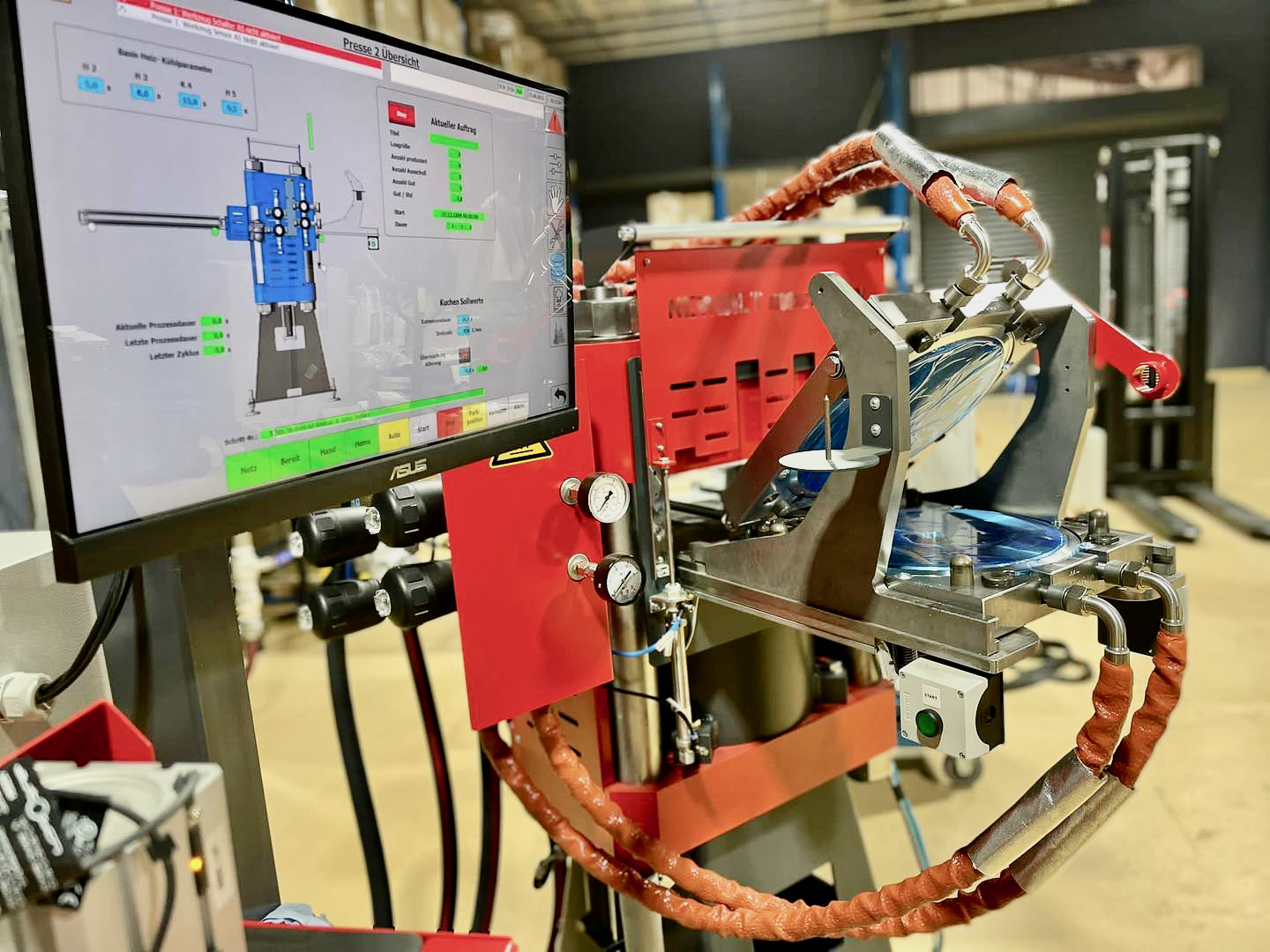

This call seems to have been answered. Various new pressing plants are being put into operation. The latest announcement comes from Mecklenburg-Vorpommern. Matter Of Fact is the name of the new plant, which aims to produce 30,000 records per month. Founder Andre Kronert, who is a DJ and label owner himself, posted on his Facebook page: "We don't press for major labels!", which is a bold statement but sums up the frustration of musicians and labels who are faced with production times of up to 12 months due to material shortages and high production values of major labels.

Indie artists and labels compete with the big names

Normally there is not much overlap between the commercially successful stars and the indie guild, but with vinyl pressings, they all come together. Adele's last album had a unit count of 500'000 and albums by other big artists like Billy Eilish probably have numbers well above those of any indie label or artist. For the pressing plants, these orders are very lucrative and are understandably prioritised.

It is now also possible to press vinyl in Switzerland again. The company Adon in the canton of Aargau has installed a new machine and is pressing the first records in the country since 2004. Like Matter Of Fact, Adon focuses on pressing smaller quantities, which in turn benefits indie artists and labels alike. Other examples that have recently entered the business with a similar intention are Mobineko in Taiwan. Back in February, DJ Mag asked the question "Can this pressing plant revolutionise the vinyl market?", and the same question ("Can this new pressing plant solve the vinyl crisis?") was asked by The New Statesman on the occasion of the opening of Press On Vinyl in Middlesbrough.

More machines, less waiting time

From the point of view of an indie label, the problems of vinyl production are complex and not easy to solve, and the production aspect is only one of many to consider. The production of smaller quantities of records is symptomatic of the evolution of our music consumption. With almost every song ever produced available anytime, anywhere, listening habits have also changed. Nowadays, it is incredibly difficult for artists to reach as large an audience as the artists mentioned above because due to the choice we have today, everyone can listen to what he/she/they want. Not to mention that hardly anyone listens to an album more than once nowadays.

This also means that it is difficult for artists and labels to sell the quantities they need to survive financially. With any mass product, there are basic costs that do not vary much and more or less determine the price per unit. This means that when you produce small quantities, the unit price is high and the more you produce, the lower it becomes. In short, and not to get too specific: If you want to make a reasonable margin that allows you to recoup your investment, you have to press more (and therefore sell more) or sell the product at a higher price (and hope that customers are willing to pay it).

Whether this new pressing plant will bring the expected relief to the strained vinyl market remains to be seen. Having more production capacity is certainly a good step. The question is how long it will take for these new plans to be 100% operational. Since the process is tied to experienced technicians and depends on production chains such as galvanic for the stamper or the PVC granulate, the problem of long waiting time will not be solved just by putting more machines in new factories –and it definitely doesn't solve the problems indie labels have to deal with these days.

Words by Dominik André. He writes about DJ culture, music nerd stuff and sometimes shares thoughts about the music business. He runs the record label Subject To Restrictions Discs.